PCB tarotsari ne mai mahimmanci a cikin kera na'urorin lantarki.Haɗin da ya dace na allunan kewayawa (PCBs) yana tabbatar da aiki da amincin na'urorin lantarki.A cikin wannan shafin yanar gizon, za mu shiga cikin mahimman abubuwan haɗin PCB, tattauna mahimmancinta, da kuma haskaka fa'idodin ayyukan taro na ƙwararru.

Koyi game da taron PCB.

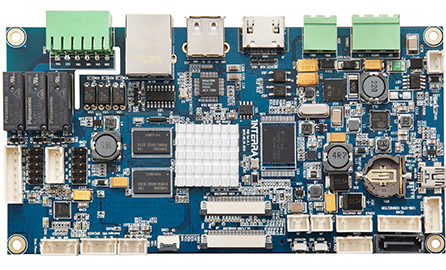

PCB taro ya ƙunshi aiwatar da hawa kayan aikin lantarki akan PCB mara kyau.Ya haɗa da manyan hanyoyi guda biyu: fasaha ta hanyar rami (THT) da fasahar hawan dutse (SMT).Fasaha ta hanyar rami ta ƙunshi shigar da jagora zuwa cikin ramuka a cikin PCB, yayin da fasahar dutsen ƙasa ta ƙunshi kayan aikin siyar da kayan kai tsaye zuwa saman allon kewayawa.

Muhimmancin taron PCB da ya dace.

1. Ayyuka: PCB da aka haɗa da kyau yana tabbatar da aikin al'ada na kayan lantarki.Rashin haɗuwa yana iya haifar da gazawar PCB, gajeriyar kewayawa, ko ma cikakkiyar gazawa, yana haifar da gyare-gyare masu tsada ko sauyawa.

2. Amincewa: Babban taro mai inganci yana tabbatar da amincin kayan aikin lantarki kuma yana rage haɗarin gazawar yayin ayyuka masu mahimmanci.Ingantattun dabarun sayar da kayayyaki na iya hana haɗin kai mara kyau da tabbatar da kwanciyar hankali, guje wa matsalolin tsaka-tsaki.

3. Miniaturization: PCBs suna ƙara ƙarami kuma sun fi rikitarwa, kuma taro na hannu ba zai yiwu ba tare da fasaha na ci gaba.Ƙwararrun sabis na taron PCB suna amfani da kayan aiki mai sarrafa kansa kamar na'urori masu ɗauka da wuri don sanya daidaitattun abubuwan da aka gyara, har ma a kan ƙananan allon da'ira.

4. Ingancin lokaci: Ayyukan Maɓaki Masu Kwararru suna da ƙwarewa, gwaninta, da kayan sana'a na musamman don jera lokacin samar da taro.Wannan yana tabbatar da saurin juyawa kuma yana bawa masana'antun damar biyan buƙatun kasuwa da ƙayyadaddun ƙayyadaddun lokaci.

Abũbuwan amfãni na ƙwararrun sabis na taro na PCB.

1. Ƙwararrun Ilimi: Ƙwararrun sabis na taro suna ɗaukar ƙwararrun ƙwararrun ƙwararrun ƙwararrun fasaha waɗanda suka ƙware a fasahar taron PCB, sun fahimci sabbin ka'idojin masana'antu, kuma sun fahimci nau'ikan sassa daban-daban.Kwarewar su tana tabbatar da ingantacciyar jeri, daidaitaccen siyarwar, da kuma gwajin daidaitattun PCBs.

2. Kayan aiki: Ƙwararrun sabis na taro suna saka hannun jari a cikin kayan aiki na zamani kamar na'urar buga stencil, tanderun wuta, da injunan taro na atomatik.Waɗannan kayan aikin ci-gaba suna tabbatar da daidaitattun jeri na sassa, siyar da kaya, da cikakken dubawa don samar da PCBs masu inganci.

3. Quality iko: Professional taro ayyuka manne wa m ingancin iko matakan don tabbatar da aminci da kuma ayyuka na taru PCBs.Suna bin ka'idodin masana'antu, suna gudanar da cikakken bincike, kuma suna amfani da hanyoyin gwaji na ci-gaba kamar Binciken gani Automated (AOI) don gano duk wani kuskure da gyara su cikin sauri.

4. Cost-Tasiri: Duk da yake outsourcing PCB taro na iya ze m, shi ya tabbatar da zama wani kudin-tasiri bayani a cikin dogon gudu.Ayyukan taro na sana'a sun kawar da buƙatar kayan aiki masu tsada, horo da aiki.Bugu da ƙari, rage lahani na PCB da fitarwa mai inganci suna ba da gudummawa ga tanadin farashi gabaɗaya.

Don taƙaitawa, taron PCB yana taka muhimmiyar rawa wajen kera na'urorin lantarki.Zaɓin sabis na taro na ƙwararru yana tabbatar da aiki, aminci da ƙimar farashi.Yin aiki tare da masana a fagen yana adana lokaci, yana kawar da kurakurai, kuma yana ba da garantin PCB masu inganci, a ƙarshe yana amfana da masana'antun da masu amfani da ƙarshe.Don haka, idan kuna buƙatar taron PCB, la'akari da fa'idodi da ƙwarewar sabis na ƙwararru don sakamako mafi kyau.

Lokacin aikawa: Satumba-06-2023